12,04€ Original price was: 12,04€.9,68€Current price is: 9,68€. (8,00€ tax not included)

20% Off

12,04€ Original price was: 12,04€.9,68€Current price is: 9,68€. (8,00€ tax not included)

20% Off

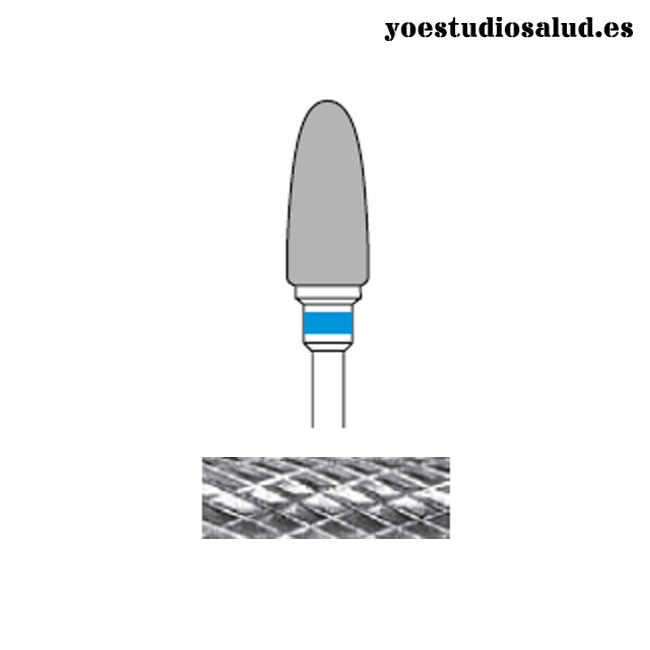

CARBIDE BUR 5410

CARBIDE BUR 5410

Tungsten Carbide Burr 5410, for handpiece, for cutting plaster and resin. ISO 500.104.274190.060. Cutting 10 for finishing of non-precious alloys and for skeletons. For coarse reduction of all dental materials without tearing the surface.

248 in stock (can be backordered)

248 in stock (can be backordered)

Tungsten Carbide Burr 5410, for handpiece, for cutting plaster and resin. ISO 500.104.274190.060. Cutting 10 for finishing of non-precious alloys and for skeletons. For coarse reduction of all dental materials without tearing the surface. Equivalent to Komet H251GE.

Carbide burs are essential tools in dental laboratories. They are used for a variety of machining and finishing processes in the fabrication of dentures and other custom dental devices. These tools are specifically designed to cut dental materials, such as resins, ceramics and metals, with precision and efficiency.

One of the most outstanding features of carbide burs is their composition. They are made of tungsten carbide, an extremely hard and abrasion-resistant compound. This hardness allows them to maintain a sharp edge over extended periods of use, resulting in clean, precise cuts in a variety of dental materials. In addition, their wear resistance means they can withstand the rigorous working environment of a dental laboratory without losing their effectiveness.

Versatility is another important advantage of carbide burs in dental laboratories. They come in a wide range of shapes and sizes to suit different types of jobs, from milling metal frameworks to contouring ceramic restorations. Some common designs include round, conical, cylindrical and ball end mills, each with specific applications in the dental manufacturing process.

Precision is critical in restorative dentistry, and carbide burs offer an exceptional level of control and detail when machining dental materials. Their sharp design and ability to maintain a constant cutting speed allow dental technicians to create restorations with precise fit and smooth finish. This is crucial to ensure patient comfort and long-term functionality of dental prosthetics.

In addition to their ability to produce precise cuts, carbide burs are also known for their efficiency in the dental laboratory. Their hardness and strength allow for higher cutting speeds and longer service life compared to other cutting tools. This translates into reduced manufacturing times and lower operating costs for the lab, which can improve overall productivity and profitability.

Although carbide burs are durable and efficient, it is important to note that they require proper maintenance to ensure optimum performance. This includes regular cleaning to remove material residue and periodic inspection for signs of wear or damage. In addition, burs should be stored properly when not in use to avoid accidental damage.

In short, 5410 carbide burs are indispensable tools in dental laboratories thanks to their hardness, versatility, precision and efficiency. Their ability to cut a variety of dental materials with precision and consistency makes them a preferred choice for dental technicians looking to provide high-quality dental prosthetics to their patients.

Related Products

14,45€Original price was: 14,45€.11,95€Current price is: 11,95€. (9,88€ tax not included)2 in stock (can be backordered)